We're here to help: Easy ways to get the answers you need.

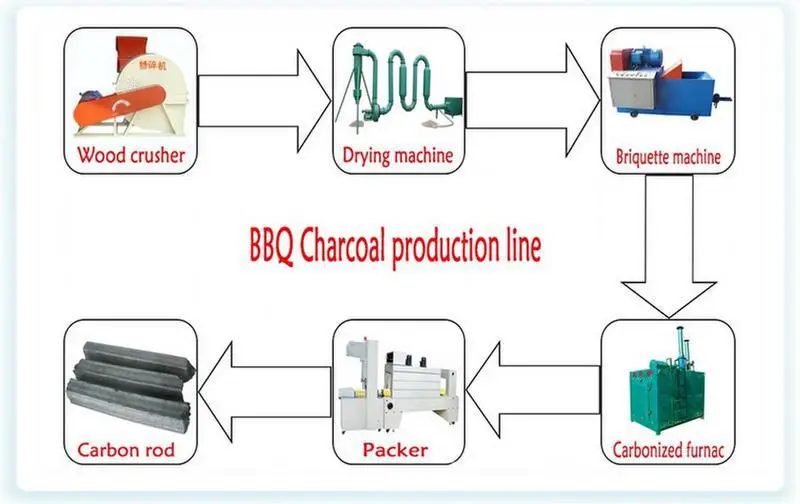

professional in wood sawdust charcoal production line/curhser machine / briquette machine/carbonization furnace

Wood crusher machine

If your raw material is too big,you need to crush it first

Wood crusher is a new type machine of producing sawdust which could make the wood, argo waste and tree branches into sawdust. It’s necessary to use a wood crusher if your raw material is raw wood (tree branch, tree root and etc.)

The machine is made of cutting device, crushing device and air blower. The woods are cut into small pieces through the cutting device and sent into the second device to crush without drying them. The final sawdust will be sent to the gathering palce by the air blow. The whole machine only need one electric motor, with simple structure, working stable, low energy consumption, high output and low cost.

Technical parameter

main technical parameters

|

Machine Model |

600 |

800 |

|

Cutter diameter (mm) |

600 |

800 |

|

Cutterhead speed(r/min) |

970 |

740 |

|

Thickness mm Length mm chips |

2-15 2-50 |

2-15 2-50 |

| Feeding mode |

Under oblique |

Under oblique |

|

I feed size mm |

220×240 |

250×250 |

|

Capacity t / h |

1-3 |

3-5 |

|

Motor Power kw |

15 |

30-37 |

|

Mm maximum diameter of the timber cutting |

170×220 |

200×250 |

|

A material way |

Oblique on the |

Oblique on the |

|

Kg whole weight |

1192 |

1680 |

|

Overall dimensions (L × W × H) |

2002×1175×1360 |

2008×1400×1492 |